refractometer calibration use and maintenance|brix % to refractive index : sourcing It is absolutely necessary to properly maintain the instrument to obtain the best possible accuracy. This includes thoroughly cleaning the prism and well after each sample and .

webUPrinting, Van Nuys. 80,032 likes · 104 talking about this · 162 were here. We provide trusted custom printing solutions for all your business needs.

{plog:ftitle_list}

WEBNegozi Cassino. Uffici Cassino. 14 agenzie immobiliari a Cassino: consulta su .

Steps for Calibration. Inspect the refractometer prism for scratches, chips, separations or other aberrations that may interfere with proper readings (Fig. 9). If dusty, rinse with water and wipe .

tensile testing machine insize

Dept. of Plant Sciences, Mail Stop 2 University of California, Davis One Shields Avenue Davis, CA 95616. Telephone: (530) 752‐6941; Fax: (530) 754‐4326 If there is a discrepancy with the reading and the value you know to be true, then you will need to calibrate your refractometer. The reading error (or tolerance) taken at a set .This document provides instructions for calibrating, using, and maintaining a refractometer to accurately test fruit sugar content. It discusses: 1) Choosing between analog and digital refractometers and their proper use. 2) The .

standard operating procedure for refractometer

Calibrating a refractometer is an essential task to ensure accurate measurements and reliable results. Whether you are using a refractometer for home brewing, . It is absolutely necessary to properly maintain the instrument to obtain the best possible accuracy. This includes thoroughly cleaning the prism and well after each sample and .

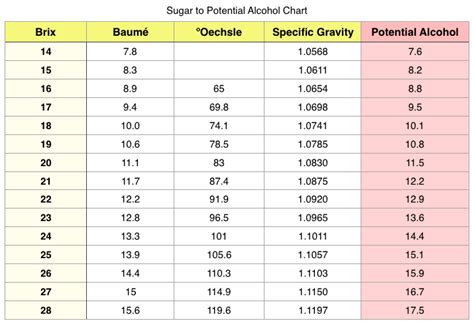

• Refractometer Calibration, Use and Maintenance • Flavor is the Final Frontier • Table Grape BIFS Field Day • Grape Day at the Kearney Ag Center • Local Meetings and Events • Publications from the University of California Vine Lines (Continued on page 2) Harvest season will soon be upon us in the San Joaquin Val-Digital Refractometer Care and Maintenance A little training can go a long way in keeping your digital refractometer in perfect working order for years to come. Below are our suggestions, guidelines, or, if you prefer, hard and fast laws to share with your employees! Another advantage of calibration is the maintenance and care it gives the refractometer. This can extend the life of the device and improve durability. How often do you have to adjust the refractometer? Calibration of . How to Use a Refractometer: Calibration and Use of Analog Refractometers. Calibrate the refractometer with a standard solution before use. Since the reading will be affected by temperature changes, it is best to calibrate at the temperature of the test environment. . Refractometers require very little maintenance. When the measurement is .

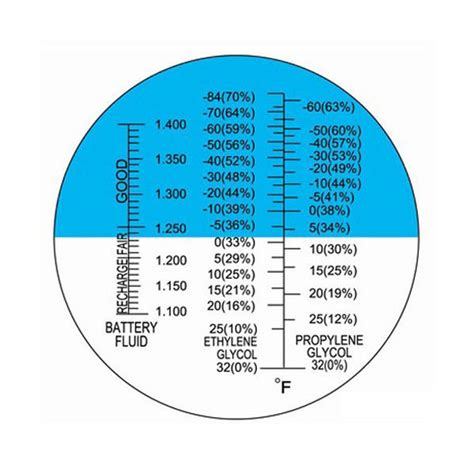

refractometer chart

refractometer brix conversion chart

What type of refractometer should you use? There are two handheld refractometers for use on the shop floor: analog and digital. Most maintenance personnel and machinists are familiar with the analog refractometers: flip-up lens cover, add a drop of coolant, close the lens cover, look through the eyepiece and read the scale.

In principle, calibration on a refractometer is not necessary. During normal use, a measurement will not shift. The same goes for maintenance. However, it is important to keep the refractometer clean. However, do not use water to clean the prism. This is to prevent water from entering the instrument. Clean the prism with a dry or slightly damp .

After refractometer calibration, use paper to absorb the water traces on the cover and prism surface. After adjusting the zero position, keep the refractometer from vibration. Do not use the method of falling to remove the residual water. .

Cl inical refractometers are common in-house screening tools for measuring urine specific gravity (USG) with a minute volume of urine. 1 Veterinarians use USG to determine the concentrating ability of the kidneys, pinpoint the anatomic location of any abnormalities, and assess hydration status. 1-3 This article describes how refractometers work, refractometer .Refractometer Calibration and Quality Control Procedure... 168. Appendix O2. Refractometer Verification Log... 170. Appendix O3. Refractometer Maintenance Log... 172. Appendix P1. Refrigerator and Freezer Temperature Mapping Procedure... 174. Appendix P2. Refrigerator and Freezer Daily Temperature Verification Log . If you’re new to using a refractometer, this is the video for you. We will break down the basics of a refractometer in a simple, easy-to-understand way, ensu. Apply 1.40229, NIST certified calibration oil and to press “CAL” or “MENU” key to cancel. 3. Span 1.51416 – Press MENU will prompt to Apply 1.51416, NIST certified calibration oil and to press “CAL” or “MENU” key to cancel. 4. Add/Delete/Edit – When selecting any of these modes a “Warning” will appear “Incorrect use of

Digital Refractometer Care & Maintenance Keep Measuring Surface Clean The most important piece of information we can give you is, “Keep the Measuring Surface Clean!” It is extremely important to thoroughly clean the refractometer measuring surface after each use to ensure the most accurate readings and to prevent cross-contamination. Ensure that it is focused and set to zero or the calibration mark. Use the calibration screw or knob to make any necessary adjustments. Step 6: Verify the calibration – Check the reading on the scale. It should match the known refractive index provided by the calibration liquid within an acceptable range.

Discover the step-by-step process of using a refractometer for accurate measurements. From understanding its function to maintaining its accuracy, this guide covers everything you need to know.. Understanding Refractometers. Refractometers are essential tools used in various industries, such as food and beverage, pharmaceuticals, and automotive, .Refractometer calibration fluids come with certificates and are available in a wide range of values, suited to your refractometer. Step 8: When the refractometer is done factoring in the R.I. value of the calibration fluid it will ask the user to enter the certified value which is printed on the label of the refractometer calibration fluid .

A. Krüss Optronic GmbH Alsterdorfer Straße 276 – 278 22297 Hamburg - Germany. Phone: + 49 (0) 40 5143 17 0 E-Mail: [email protected] Temperature Calibration: Procedure: Perform the temperature calibration using calibrated thermometer at a temperature at 20°C and 25°C using purified water maintained at 20°C and 25°C respectively. Tolerance Limits: ± 0.5°C of the specified temperatures. Note: If instrument does not comply with any of the calibration parameters, then follow the relevant .If your refractometer has a focusing adjustment, use it to achieve a sharp and clear image of the boundary between light and dark areas. This ensures accurate measurements. Cover Plate: If the refractometer has a cover plate, open it to access the prism. Application of Calibration Standard: Apply a few drops of the calibration standard onto the .

Components of a refractometer (refer to figure 1): Measuring prism. Illuminator flap/cover. Eye piece. Bimetallic strip (placed internally) Calibration screw. Scales. A traditional handheld refractometer consists of a measuring prism that you place a few drops of the liquid to be examined on with a flap to cover the sample.

refractive index brix conversion chart

Refractometer Calibration and Quality Control Procedure... 168. Appendix O2. Refractometer Verification Log... 170. Appendix O3. Refractometer Maintenance Log... 172. Appendix P1. Refrigerator and Freezer Temperature Mapping Procedure... 174. Appendix P2. Refrigerator and Freezer Daily Temperature Verification Log . Improper handling and maintenance. Refractometers are delicate instruments that require proper handling and maintenance to ensure their longevity and accuracy. Mishandling the device can lead to damage or misalignment, affecting the precision of your measurements. . Regularly calibrating your refractometer using certified calibration .Preventive maintenance is key to the performance and longevity of your density meter or refractometer. Combined with our Calibration service, pre-planned, periodic maintenance provides you with complete confidence that your measuring instrument will achieve: Accurate and repeatable results; Extended lifetime; Safe and reliable operationSome models use a special calibration liquid while others use distilled water. Lift the daylight plate and place 2 to 3 drops of the calibration liquid on the prism assembly. . Adjust the calibration screw so that the refractometer reads exactly zero. Clean the daylight plate and the main prism assembly with a soft, damp cloth. Place 2 to 3 .

Calibration determines the measurement accuracy of your density meter and refractometer. With routine calibration and adjustment, you can measure safely, ensure complete compliance and avoid the costs of inaccurate measurements. . Preventive maintenance ensures you maintain productivity, extend equipment life and enable your meters to perform .

14. Treat handheld refractometers with care for continuously accurate results. Optical and digital handheld refractometers require little maintenance, often only requiring a zero calibration with water. For high range instruments that don’t have a zero point, use a sugar sample or for optical instruments, a solid test plate. The refractometer readout shown above is measuring 30 degrees Brix. Other Types of Refractometers. Digital refractometers require a drop of the tested solution to be placed in a well. That well is illuminated by a light source, usually an LED light, and the meter interprets the light transmission into refractive index or whatever unit of measure the .Digital refractometers often feature built-in temperature compensation and user-friendly interfaces, making them suitable for laboratory use and quality control applications. Abbe Refractometers. Abbe refractometers utilize a prism and a collimated light source to measure refractive indices across a wide range of wavelengths.

does anyone service rayner refractometer

WEBAs apostas em Under/Over são divididas em três categorias principais: linhas de Under/Over, mercados de gols e apostas de placar. As linhas de Under/Over são as mais simples e populares, pois envolvem apenas escolher se o total de golos marcados em um jogo será acima ou abaixo da linha estabelecida pelas casas de apostas. Já os .

refractometer calibration use and maintenance|brix % to refractive index